- Solution

- Product

- About Us

- Support

01Steelworks ladle, electrical and mechanical facilities, flare stacks, substation facilities, metal manufacturing, automobile manufacturing, electronic parts, food processing, packaging, adhesion, welding

02Failure prevention and quality assurance through temperature monitoring: It is operated for the purpose of quality assurance and improvement through non-contact automatic temperature measurement in steel mills, large machinery facilities, substation facilities, and metal manufacturing (processing, adhesion, welding) processes where temperature and processing time for each process may affect quality.

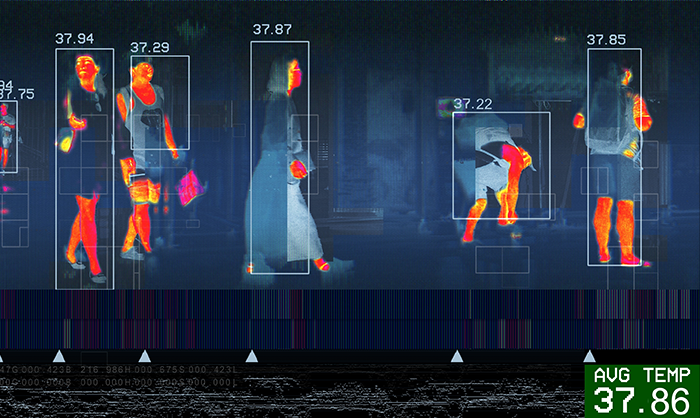

01Screening people with fever

02Livestock hygiene

03Quality of life can be improved through screening for people and animals with high contagious diseases such as flu, SARS, Zika fever, MERS, and COVID-19 that appear every year and maintaining health in humans and animals.